by Ben Poole, Ben Poole Editorial Services

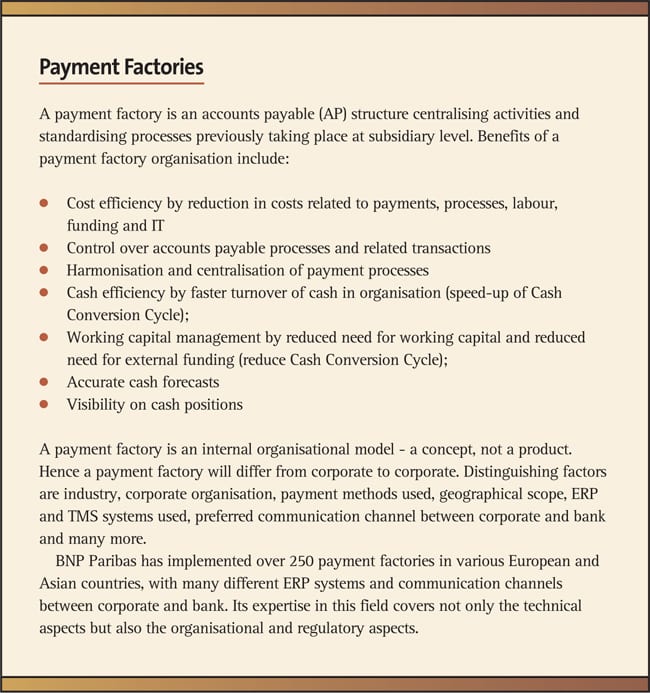

A popular workshop on the opening day of BNP Paribas’ 7th Cash Management University looked at best practices in setting up a payments factory, and also explored the possibilities that exist for driving similar efficiencies on the collections side. The workshop included two corporate case studies from Uwe Boesl, general manager at Novartis Investment, and Bertrand Janssens, treasurer at Nexans. They were joined on the panel by George Stein, product marketing director with ACE, and Filipe Simao, Head of Client Advisory, BNP Paribas Cash Management.

Corporate Case Study: Novartis

Novartis, a healthcare company based in Basel, Switzerland, began implementing a treasury and finance transformation programme in 2012. Uwe Boesl explained that one of the key objectives of this programme was to have full control and visibility of both the financial risk and liquidity of the group, to maintain global cash pool structures wherever appropriate and to concentrate cash management with a select number of core banks. The programme also aimed to develop and streamline the organisation’s payment infrastructure in order to route payment in the most cost efficient way.

Sign up for free to read the full article

Register Login with LinkedInAlready have an account?

Login

Download our Free Treasury App for mobile and tablet to read articles – no log in required.

Download Version Download Version